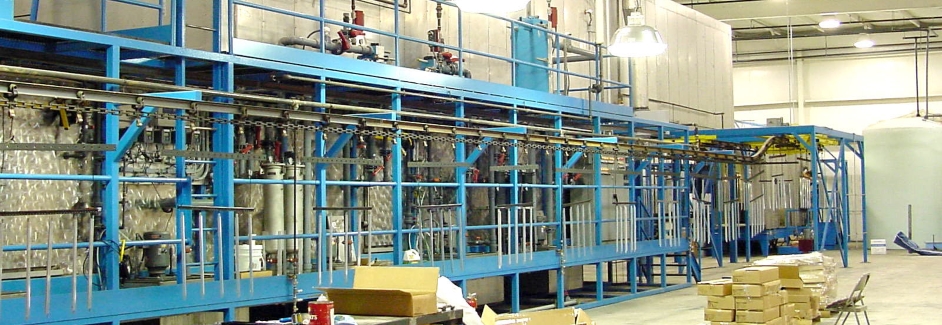

We create complex, automated turn-key finishing systems that reach new levels of production efficiency and energy savings. We help maximize productivity while striving to be cost-effective. Bethel also provides upgrades and can retrofit components for existing coating lines.

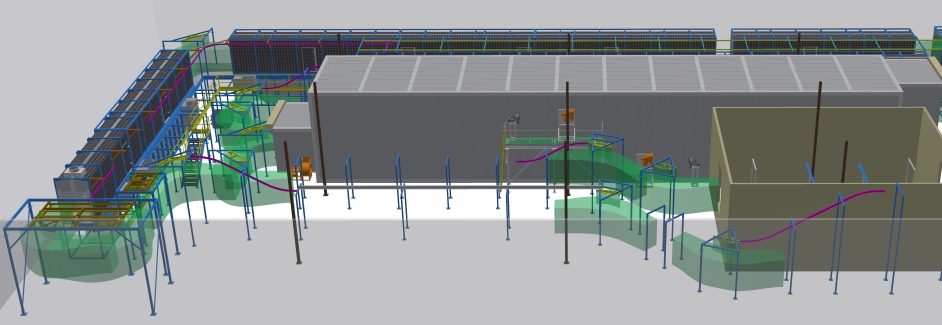

The Bethel team will handle the design and coordinate the installation of your finishing system. It has "Complete Capability" with regards to providing turnkey finishing systems to meet your production needs. We are capable of designing and installing environmental equipment, including wastewater treatment facilities and air makeup systems.

We will work closely with you in the initial stages of your project, generating concept drawings as we determine what best meets your needs. It is important to build relationships based on experience and trust. Therefore, each job is assigned an engineer that follows the system "on-site" through completion. These relationships have created the most efficient, highest-quality finishing systems possible.

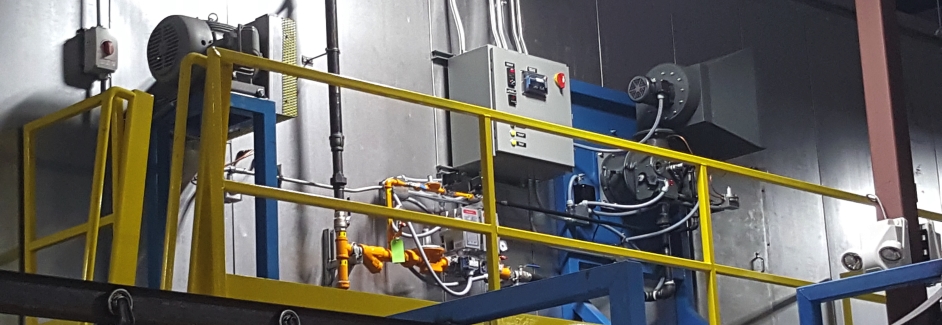

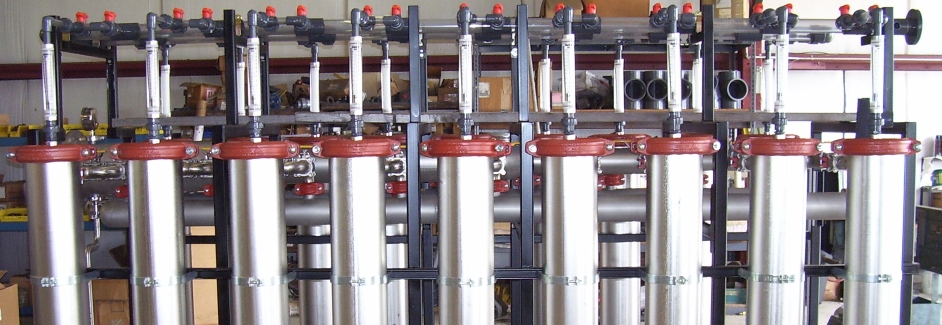

Our history in the turnkey coating systems business covers everything from small custom chain on-edge units to large monorail systems capable of coating parts weighing over 2000 pounds. Over the years, we have fabricated large liquid systems and bulk storage facilities. Our services also include dismantling, moving, and reinstalling existing systems.

When the design is finalized, we will begin to engineer the various components of your finishing system. All structural components are checked for load-bearing capabilities, flow rates are checked, and heating and electrical loads are determined. Each component is carefully sized and chosen, so your system works right the first time.

Bethel Engineering can provide supplier coordination by working with various paint, powder, and chemical suppliers. Throughout the years, we have established great working relationships with several name-brand suppliers. We can introduce you to them as the project progresses, or we can work with the suppliers of your choice.

TURN-KEY SYSTEMS INCLUDE:• Conceptual Drawings

• Engineering & Design

• Project Management

• Installation

• Environmental Equipment

• Waste Water Treatment Facilities

• Air Make-up Systems

• Large and Small Monorail Systems

• Large Liquid Systems

• Bulk Storage Facilities

• Supplier Coordination

SYSTEM SERVICEBethel Engineering "Services what we Build" and complete repair service on other coating systems. With our full fabrication facilities, we can re-manufacture worn or damaged components, oven repair, and custom rack designs.

|

|

|