Finishing Systems

Bethel is a leader in the finishing industry and can provide you with an economically priced, world class finishing system. We can analyze your coating requirements and make recommendations to best facilitate your company's individual finishing needs. We configure each system to the unique requirements of our individual customers. We make sure each system is designed to meet your needs and install to perform as expected.

We create complex, automated turn-key finishing systems that reach new levels of product efficiency and energy savings. We help maximize productivity while striving to be cost effective. Bethel also provides up-grades and can retrofit components for existing coating lines.

The Bethel team will handle the design and coordinate the installation of your finishing system. It has "Complete Capability" with regards to providing turnkey finishing systems to meet your production needs. We are capable of designing and installing environmental equipment including waste water treatment facilities and air make up systems.

We will work closely with you in the initial stages of your project, generating concept drawings as we determine what best meets your needs. It is important to build relationships based on experience and trust. Therefore, each job is assigned an engineer that follows the system "on-site" through completion. These relationships have proven to create the most efficient, highest quality finishing systems possible.

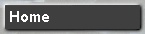

Our history in the turn key coating systems business covers everything from small custom chain on edge units through large monorail systems capable of coating parts weighing over 2000 pounds. Over the years we have fabricated large liquid systems and bulk storage facilities. Our services also include dismantling, moving, and reinstalling existing systems.

When the design is finalized, we will begin to engineer the various components of your finishing system. All structural components are checked for load bearing capabilities, flow rates are checked and heating and electrical loads determined. Each component is carefully sized and chosen so your system works right the first time.

Bethel Engineering can provide supplier coordination working with various paint, powder, and chemical suppliers. Throughout the years, we have established great working relationships with several name brand suppliers. We can introduce you to them as the project progresses or we can work with the suppliers of your choice.

Bethel is a leader in the finishing industry and can provide you with an economically priced, world class finishing system. We can analyze your coating requirements and make recommendations to best facilitate your company's individual finishing needs. We configure each system to the unique requirements of our individual customers. We make sure each system is designed to meet your needs and install to perform as expected.

We create complex, automated turn-key finishing systems that reach new levels of product efficiency and energy savings. We help maximize productivity while striving to be cost effective. Bethel also provides up-grades and can retrofit components for existing coating lines.

The Bethel team will handle the design and coordinate the installation of your finishing system. It has "Complete Capability" with regards to providing turnkey finishing systems to meet your production needs. We are capable of designing and installing environmental equipment including waste water treatment facilities and air make up systems.

We will work closely with you in the initial stages of your project, generating concept drawings as we determine what best meets your needs. It is important to build relationships based on experience and trust. Therefore, each job is assigned an engineer that follows the system "on-site" through completion. These relationships have proven to create the most efficient, highest quality finishing systems possible.

Our history in the turn key coating systems business covers everything from small custom chain on edge units through large monorail systems capable of coating parts weighing over 2000 pounds. Over the years we have fabricated large liquid systems and bulk storage facilities. Our services also include dismantling, moving, and reinstalling existing systems.

When the design is finalized, we will begin to engineer the various components of your finishing system. All structural components are checked for load bearing capabilities, flow rates are checked and heating and electrical loads determined. Each component is carefully sized and chosen so your system works right the first time.

Bethel Engineering can provide supplier coordination working with various paint, powder, and chemical suppliers. Throughout the years, we have established great working relationships with several name brand suppliers. We can introduce you to them as the project progresses or we can work with the suppliers of your choice.

Automated Material Handling Systems

Bethel Engineering invests a lot of time and effort assisting each of our customers with their needs, especially when it comes to material handling systems. No matter the industry, let us determine which material handling operations can benefit you.

Our material Handling Systems can give your company a competitive edge. We will work closely with you to determine which operations should be automated and the most cost effective solution. Each system is custom designed to address our customers' specific requirements.

Whether you need a completely new Material Handling System or want to incorporate into your current system, Bethel can help. We work with our customers to design a system specifically tailored to the existing facility, budget, and time constraints. Our systems range from basic pick and place to fully automated manufacturing lines.

Our team works one on one with our customers to coordinate each and every system. We offer complete installation services and so much more. We encourage our customers to be involved from design to start up. For more information on what we have to offer you, Contact Us.

Bethel Engineering invests a lot of time and effort assisting each of our customers with their needs, especially when it comes to material handling systems. No matter the industry, let us determine which material handling operations can benefit you.

Our material Handling Systems can give your company a competitive edge. We will work closely with you to determine which operations should be automated and the most cost effective solution. Each system is custom designed to address our customers' specific requirements.

Whether you need a completely new Material Handling System or want to incorporate into your current system, Bethel can help. We work with our customers to design a system specifically tailored to the existing facility, budget, and time constraints. Our systems range from basic pick and place to fully automated manufacturing lines.

Our team works one on one with our customers to coordinate each and every system. We offer complete installation services and so much more. We encourage our customers to be involved from design to start up. For more information on what we have to offer you, Contact Us.

Wood Treating Systems

As with all systems provided by Bethel Engineering, we will work closely with you from concept to completion. Our Wood Treatment Systems strictly adhere to the Bethel design criteria:

• Quality Products

• Low Operating Cost

• Minimum use of plant floor space

• Minimum disruption of plant operations

• Low maintenance costs

• Ease of dissassembly and relocation of equipment

As with all systems provided by Bethel Engineering, we will work closely with you from concept to completion. Our Wood Treatment Systems strictly adhere to the Bethel design criteria:

• Quality Products

• Low Operating Cost

• Minimum use of plant floor space

• Minimum disruption of plant operations

• Low maintenance costs

• Ease of dissassembly and relocation of equipment

Our complete Turn-key systems include:

Conceptual Drawings

Engineering & Design

Project Management

Installation

Environmental Equipment

Waste Water Treatment Facilities

Air Make-up Systems

Large and Small Monorail Systems

Large Liquid Systems

Bulk Storage Facilities

Supplier Coordination

Conceptual Drawings

Engineering & Design

Project Management

Installation

Environmental Equipment

Waste Water Treatment Facilities

Air Make-up Systems

Large and Small Monorail Systems

Large Liquid Systems

Bulk Storage Facilities

Supplier Coordination

Coating Processes

Electrocoat

Powder Coating

Liquid Spray & Dip

Electrocoat

Powder Coating

Liquid Spray & Dip

Equipment

Spray & Immersion Washers

Dry-Off, Cure and Batch Ovens

Conveyor Systems

Paint Spray Booths

Waste Water Systems

Ultra Filtration Systems

Spray & Immersion Washers

Dry-Off, Cure and Batch Ovens

Conveyor Systems

Paint Spray Booths

Waste Water Systems

Ultra Filtration Systems

System Service

Bethel Engineering "Services what we Build" as well as complete repair service on other coating systems. With our complete fabrication facilities we are capable of re-manufacturing worn or damaged components, oven repair as well as custom rack design.

Bethel Engineering "Services what we Build" as well as complete repair service on other coating systems. With our complete fabrication facilities we are capable of re-manufacturing worn or damaged components, oven repair as well as custom rack design.

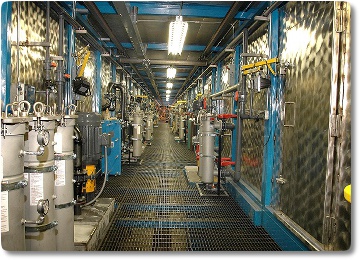

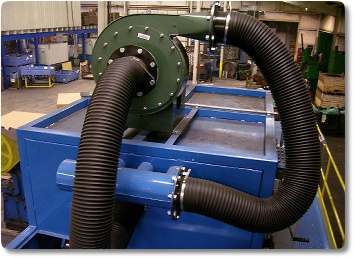

Flooding Application Module

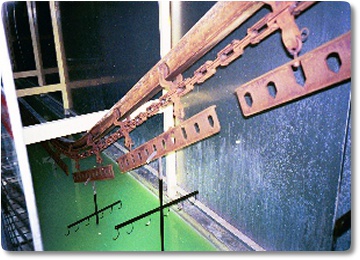

Central to the system is the application module. This module provides for a gentle 'flooding' action of the pre-blended chemical. Full coverage of the product shall be achieved with minimal turbulence or shearing of the chemical. To further aid in this, positive displacement pumps shall be used rather than centrifugal pumps.

Pre-application Blow-off Module

Before chemical application can be performed, it is important to remove any residue from the wood or lumber products. This shall aid in keeping the contamination out of the treatment chemical reservoir tank.

Post-Application Blow-off Module

After the coating process, removal of excess chemical is provided by a blow-off after module.

Conveying System with Lift Assist Tables

To facilitate the movement of the product through the system, a series of powered roller conveyors shall be provided. Also, a scissor-lift assist at the entrance and exit is incorporated.

Filtration and Cleaning

The Wood Treatment Systems are designed with multiple features to aid in filtration and cleaning such as removable strainers with bypass valves and valving to allow the cleaning water to be circulated through plumbing, pump headers and application housing.

Electrical Controls Panel

Electrical controls shall be provided for the safe starting of all electrical motors and systems. A few key control componenets include start and stop overloads, level sensor for treatment chemical reservoir, float switch, auto/manual switches for lift assist tables, three emergency stop stations, and touch screen for enhanced interface.

Central to the system is the application module. This module provides for a gentle 'flooding' action of the pre-blended chemical. Full coverage of the product shall be achieved with minimal turbulence or shearing of the chemical. To further aid in this, positive displacement pumps shall be used rather than centrifugal pumps.

Pre-application Blow-off Module

Before chemical application can be performed, it is important to remove any residue from the wood or lumber products. This shall aid in keeping the contamination out of the treatment chemical reservoir tank.

Post-Application Blow-off Module

After the coating process, removal of excess chemical is provided by a blow-off after module.

Conveying System with Lift Assist Tables

To facilitate the movement of the product through the system, a series of powered roller conveyors shall be provided. Also, a scissor-lift assist at the entrance and exit is incorporated.

Filtration and Cleaning

The Wood Treatment Systems are designed with multiple features to aid in filtration and cleaning such as removable strainers with bypass valves and valving to allow the cleaning water to be circulated through plumbing, pump headers and application housing.

Electrical Controls Panel

Electrical controls shall be provided for the safe starting of all electrical motors and systems. A few key control componenets include start and stop overloads, level sensor for treatment chemical reservoir, float switch, auto/manual switches for lift assist tables, three emergency stop stations, and touch screen for enhanced interface.

Benefits of a Bethel Material Handling System

Improved Efficiency

Increased Productivity

Reduced Labor Cost

Reduced Material Damage

Less Handling Errors

Reduced Storage and Handling Cost

Minimized Accidents

Faster Turn Around Time

Reduced Overall Costs

Maximize Use of Space

Improved Efficiency

Increased Productivity

Reduced Labor Cost

Reduced Material Damage

Less Handling Errors

Reduced Storage and Handling Cost

Minimized Accidents

Faster Turn Around Time

Reduced Overall Costs

Maximize Use of Space

Our Material Handling Packages Include:

Drawings

System Support Requirements

System Capabilities

Installation Schedule

Start up Assistance

Service Agreement

Warranties

Spare Parts List

Complete Installation Services

Drawings

System Support Requirements

System Capabilities

Installation Schedule

Start up Assistance

Service Agreement

Warranties

Spare Parts List

Complete Installation Services

Bethel has been designing, fabricating, installing and servicing products for over 15 years. No job is too big or too small. Let us assist you in

developing the product that best suits your needs. We personally design, build and stand behind the equipment we sell. Our team is devoted

to getting you the right solution and giving you the service you need after the equipment is up and running. We work closely with you from

concept to completion by providing an on-site engineer to follow your entire project. Each component is carefully analyzed and chosen so your

system works right the first time.

Our Material Handling Packages Include:

Drawings

System Support Requirements

System Capabilities

Installation Schedule

Start up Assistance

Service Agreement

Warranties

Spare Parts List

Complete Installation Services

Drawings

System Support Requirements

System Capabilities

Installation Schedule

Start up Assistance

Service Agreement

Warranties

Spare Parts List

Complete Installation Services

Our Material Handling Packages Include:

Drawings

System Support Requirements

System Capabilities

Installation Schedule

Start up Assistance

Service Agreement

Warranties

Spare Parts List

Complete Installation Services

Drawings

System Support Requirements

System Capabilities

Installation Schedule

Start up Assistance

Service Agreement

Warranties

Spare Parts List

Complete Installation Services

Conveyor Capabilites:

Skate Conveyors

Gravity Conveyors

Drag Chain

Enclosed Track

Monorail

Chains / Trolleys

Power & Free

Floor Conveyors

Skate Conveyors

Gravity Conveyors

Drag Chain

Enclosed Track

Monorail

Chains / Trolleys

Power & Free

Floor Conveyors

Conveyor Capabilites:

Skate Conveyors

Gravity Conveyors

Drag Chain

Enclosed Track

Monorail

Chains / Trolleys

Power & Free

Floor Conveyors

Skate Conveyors

Gravity Conveyors

Drag Chain

Enclosed Track

Monorail

Chains / Trolleys

Power & Free

Floor Conveyors

Safety, Storage & Handling:

Racking

Shelving

Hoppers

Carts

Work Stations

Guarding

Cages

Racking

Shelving

Hoppers

Carts

Work Stations

Guarding

Cages

Bethel Engineering & Equipment, Inc. • 13830 McBeth Road • New Hampshire, Ohio 45870 • Phone: 419.568.1100 • Fax: 419.568.1807 • info@bethelengr.com

Sitemap • © Copyright 2011, Bethel Engineering & Equipment Inc. All rights reserved. • Privacy Policy

Sitemap • © Copyright 2011, Bethel Engineering & Equipment Inc. All rights reserved. • Privacy Policy